The 3D-Cooling Company

IQ evolution specializes in small, ultra-light weight coolers in all shapes and formes. The product portfolio ranges from the development of prototypes to the series production of tailor-made components. The patented technology allows the development of geometric structures that cannot be realized by conventional methods. IQ evolution refined the 3D-metal-printing process over more than 10 years, specially to the requirements of building micro structures. We advise and develop solutions to deliver real efficiency improvements in production processes.

Advantages of 3D metal printing

Tailor-made customization

The manufacturing process does not require any moulds or tools, so a lot of customization is possible.

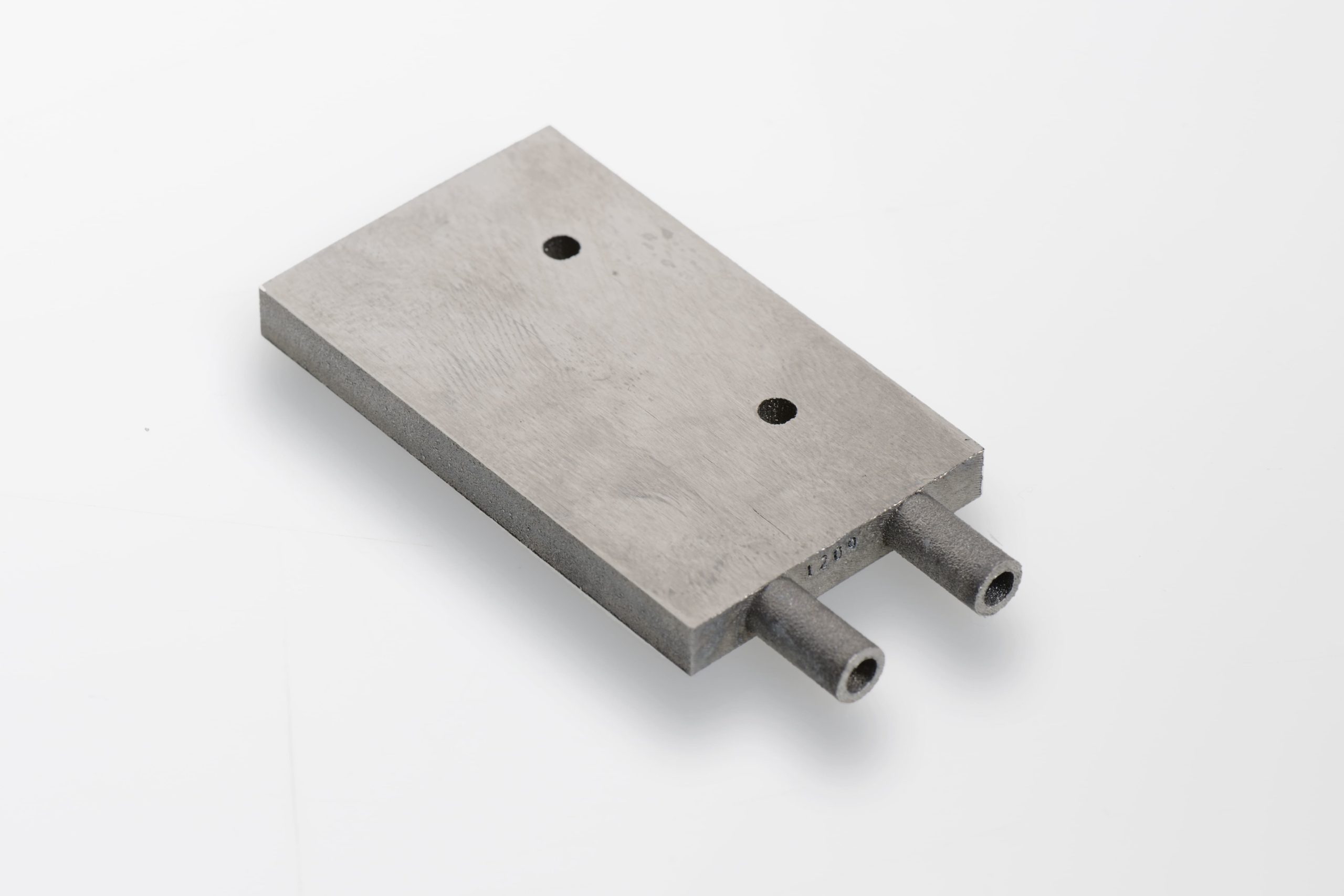

Smallest cooler for Standard components

Also available für proven packages. From cooler for TO 247 packages to double sided IGBT cooler.

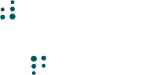

Very thin cold plates for multilayer boards

The process enables the production of very thin shapes (0,8 mm) that are suitable for economic use in Industry.

Highly efficient cooling with micro structures

Efficient cooling structures including supply areas are manufactured in the micrometer range.

Generative manufacturing processes for individual solutions

We can develop and manufacture components or product parts based on Laser Powder Bed Fusion (LPBF). For this, metal powder is applied in very thin layers and melted by a laser beam. A homogeneous metal structure is created at the points where the laser melts the powder. At the remaining areas the powder remains, which is removed at the end of the construction process. This process allows the series production of highly complex components with materials or alloys that are difficult to process.

Field of Application: Thermal Management

3D laser metal printing enables the efficient production of miniature components for a variety of applications.

IQ evolution focuses on thermal management. Highly efficient cooling components are developed and manufactured.

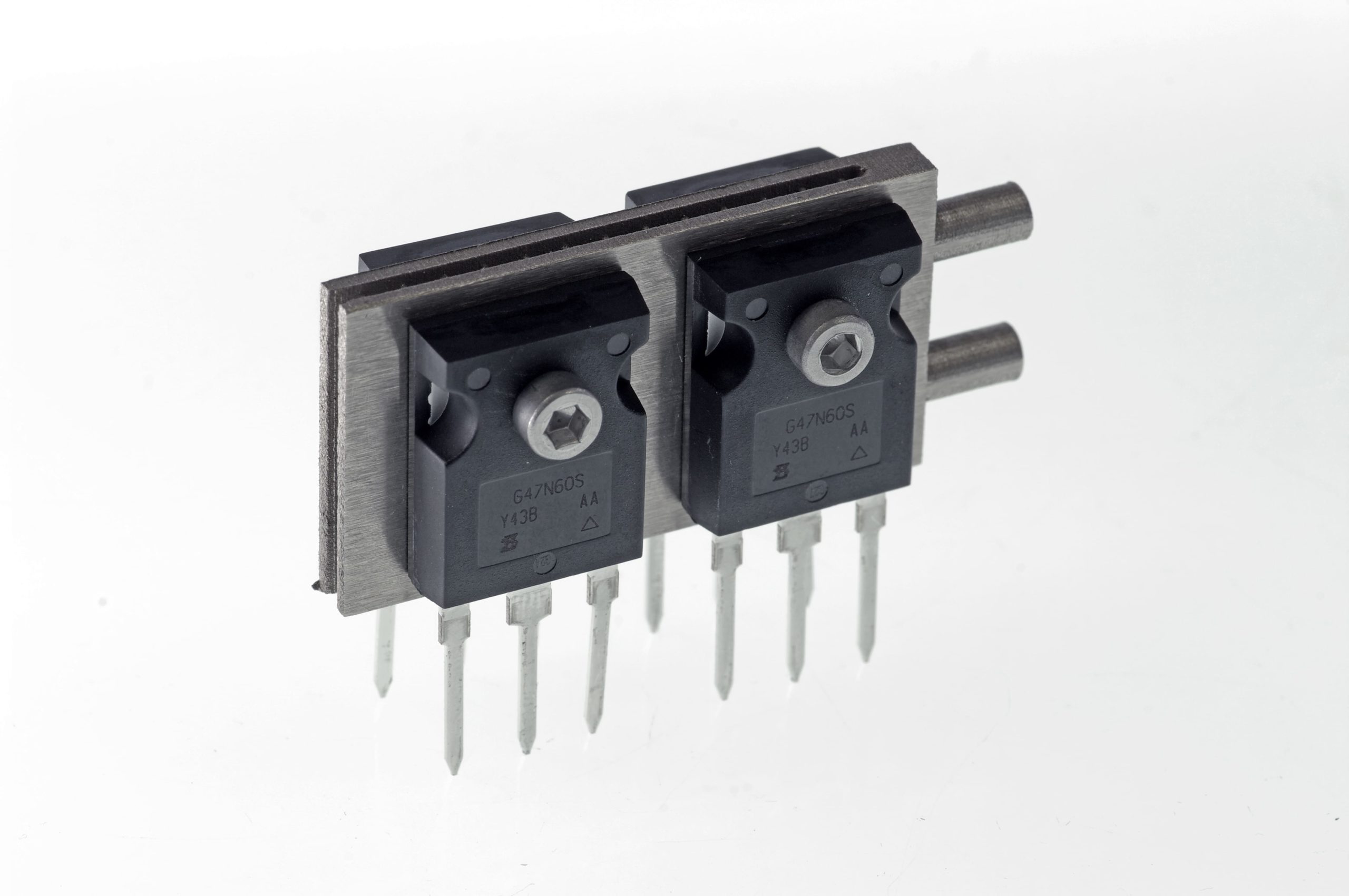

Cooling of power modules

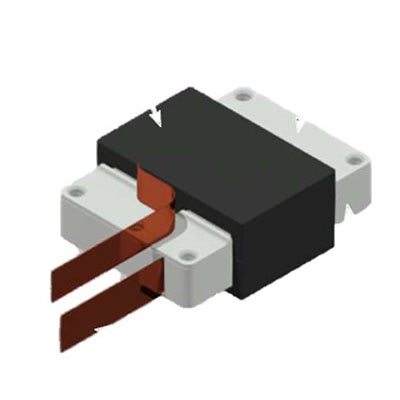

IQ-Big series

The IQ-Big series is able to cool over 3 kW using both sides. This enables your module to theoretically handle up to 300 kW.

Cooling of high power electronics based

on TO 247 housings

Small components with high power output: Cooling capacities in the smallest space from 200 Watt to 1.4 kW!

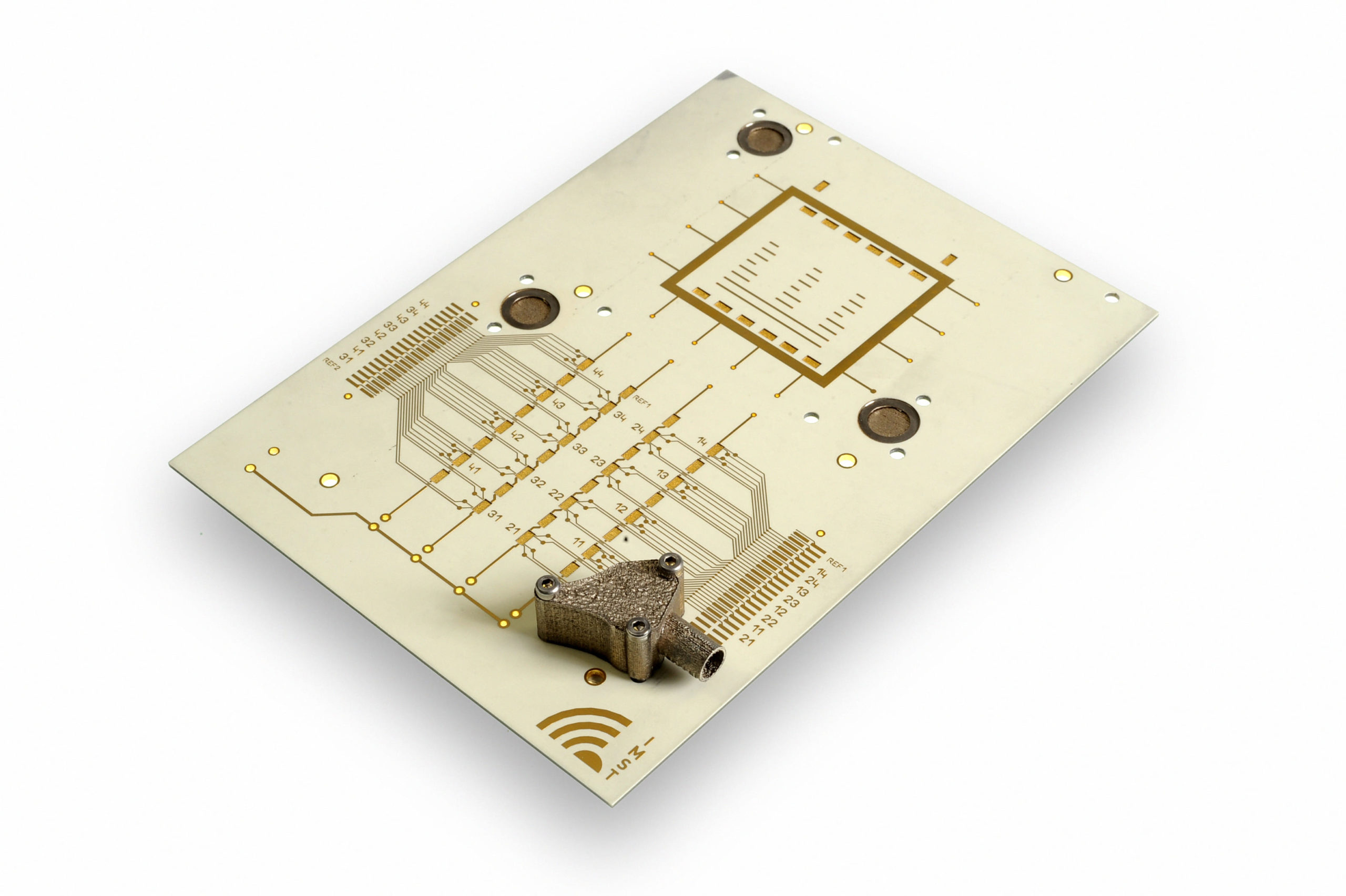

PCB cooler for integration in multi layer boards

With our 3D printing process, we set new standards for the volume of the cooler. High cooling performance even with a thickness of 0.8 mm is possible.

Inductor and capacitor cooling

With our technology, condensers and inductors

can also be individually cooled.

Press

Elektronik Praxis, Juni 2018, Metallkühler für Leistungsbauteile aus dem 3D-Laserdrucker